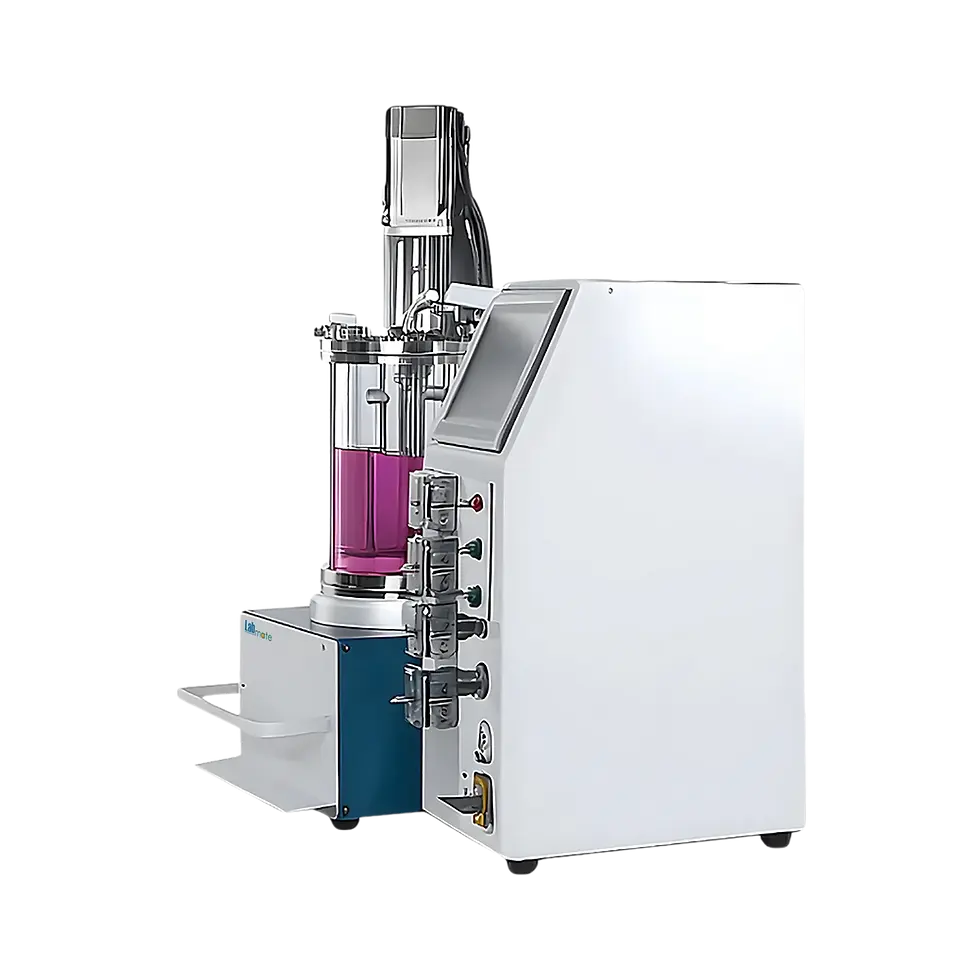

Infitek Ultra Centrifugal Mill, GM-G200

Introducing the Infitek Ultra Centrifugal Mill, GM-G200, designed for precise and efficient sample preparation.

- Achieve unparalleled grinding with a feed size of <10mm

- Attain a final fineness of <40μm

- Versatile ring sieve range of 0.08 to 2.00mm

- Robust rotor-ring sieve two-stage grinding system

- Suitable for:

- Soft samples

- Elastic samples

- Fibrous samples

- Water-bearing samples

- Oily samples

- Fatty samples

- Dry samples

- Caters to diverse laboratory needs

- Experience enhanced performance and consistent quality with our state-of-the-art centrifugal mill

PRODUCT INFO

It is applicable to a wide range of samples. Based on its efficient grinding technology and rich accessories, it adopts a two-steps grinding method of rotating knife-ring sieve system, which can perform dry and wet grinding of soft, hard, brittle and fibrous samples in a very short time.

Sample type: Soft, elastic, fibrous, water-bearing, oily, fatty, dry sample.

Application fields: Agriculture, environment, soil, electronics, RoHS testing, coal, chemistry, plastics, medicine, feed, grain, dry plants.etc.

Application Examples