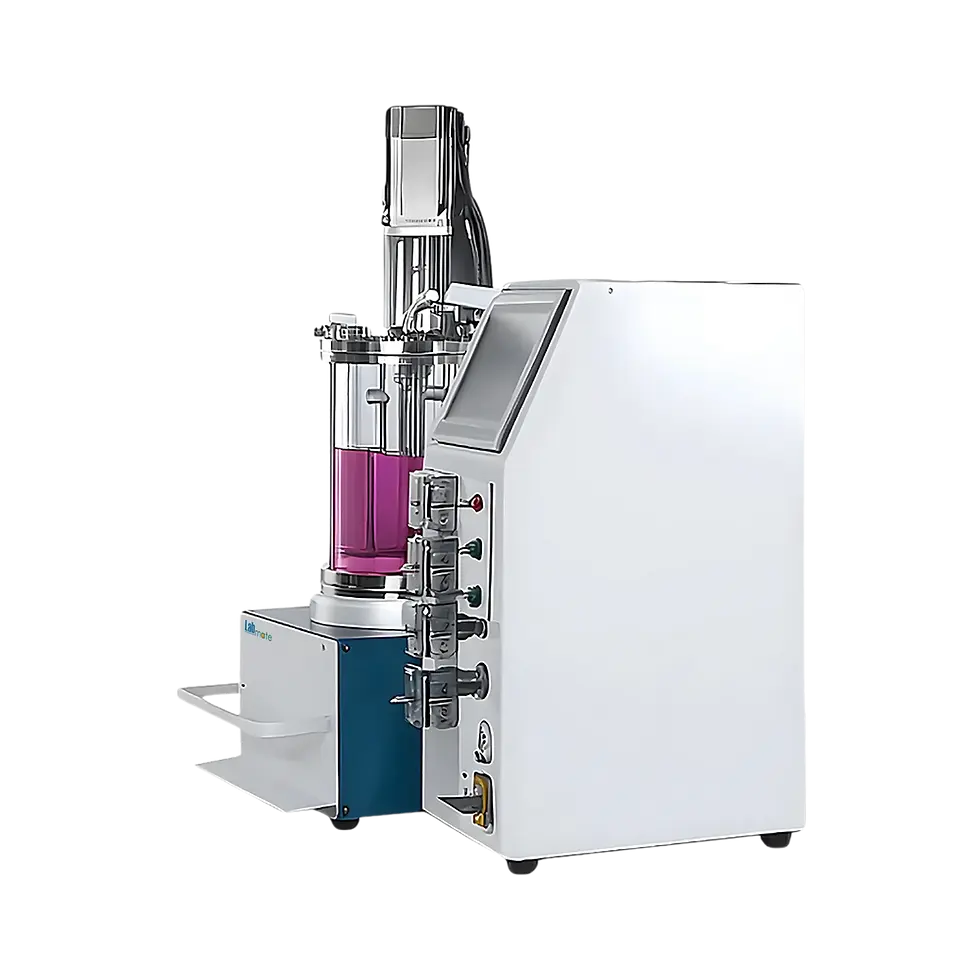

Labmate Glass Tank Bioreactor LMGTB‑A100

Discover the precision-engineered Labmate Glass Tank Bioreactor LMGTB‑A100, now available at winselluma. As an authorized distributor, we bring you this top-tier bioreactor designed for optimized cell culture and fermentation processes. Engineered with high-quality glass, it ensures durability and clarity for superior experimental results. Trust winselluma to provide unmatched reliability and support for your advanced biotechnological needs.

Product Info

Labmate Glass Tank Bioreactor LMGTB‑A100

Overview:

The Labmate Glass Tank Bioreactor LMGTB‑A100 is a versatile, laboratory-scale cultivation system designed for precise microbial fermentation and cell culture processes. Built with a borosilicate glass vessel and stainless-steel components, it offers chemical resistance, durability, and clear visibility of culture conditions. With accurate temperature control, pH and dissolved oxygen monitoring, flexible agitation, and gas handling systems, the LMGTB‑A100 supports efficient bioprocess development, optimization, and small-scale production in research and industrial settings.

Key Features:

-

5 L Tank System: Ideal for laboratory-scale fermentation and culture experiments with a maximum working volume of ~70 %.

-

High-Temperature Sterilization: Can withstand 100–130 °C, enabling reliable contamination control.

-

Transparent Glass Walls: Borosilicate glass allows easy visual monitoring of cultures without disturbance.

-

Precise Control Systems: Integrated temperature, pH, and dissolved oxygen monitoring for stable growth conditions.

-

Flexible Agitation: Variable-speed system provides uniform mixing for optimal nutrient distribution.

-

Pressure Safety Valve: Protects the system by relieving excess pressure.

-

Exhaust & Gas Integration: Supports tail gas condensers and hose connections for safe gas handling.

Applications:

The LMGTB‑A100 is ideal for:

-

Laboratory-scale fermentation and microbial culture workflows

-

Cell culture experiments requiring controlled environmental conditions

-

Bioprocess R&D, including enzyme and biopharmaceutical development

-

Small-batch production and optimization of fermentation parameters

-

Teaching and demonstration of bioprocess principles

Technical Highlights:

Specification Detail Capacity 5 L Maximum Working Volume ~70 % Sterilization Temperature Range 100–130 °C Standard Sterilization Temperature 121 °C Maximum Sterilization Temperature 131 °C Working Pressure 0.15 MPa Design Pressure 0.20 MPa Sterilization Time ~30 min @ 121 °C Tank Material Stainless steel SUS316 with borosilicate glass Diameter-to-Height Ratio ~1:2 Surface Treatment Internal & external mirror polishing Internal Surface Accuracy < 0.4 µm External Surface Accuracy < 0.6 µm Maximum Ventilation Rate Up to 2 VVM Air Filter Accuracy 0.2 µm Flow Control Type Rotameter (manual) Flow Meter Range 0–8 L/min Mixing Control Automatic PID control Mixing Speed Range 50–1000 RPM Mixing Control Accuracy ±0.5 % Temperature Sensor German Pt100 electrode Cooling Water Temp Range +5 °C to 65 °C (± 0.2 °C) Display Temperature Range 0 °C–150 °C (± 0.1 °C) pH Display Range 0.00–14.00 (± 0.01) pH Control Range 2.00–12.00 (± 0.01) Dissolved Oxygen (DO) Control Shielded DO electrode Foam Control Automatic defoamer addition via peristaltic pump Foam Control Sensitivity 10–100,000 Ω Power 220 V / 50 Hz Overall Dimensions (W × D × H) 850 × 700 × 980 mm Net Weight 88 kg Gross Weight 97 kg Standard Accessories:

-

Temperature monitoring and control interface

-

pH and dissolved oxygen sensors

-

Agitation control and adjustable stirrer

-

Pressure safety valve

-

Tail gas condenser and hose connection

-

Air filters and rotameter flow control

Optional Accessories:

-

Additional sensor modules (e.g., ORP, biomass)

-

Data logging or external PC interface

-

Sparger or alternative gas distribution options

-