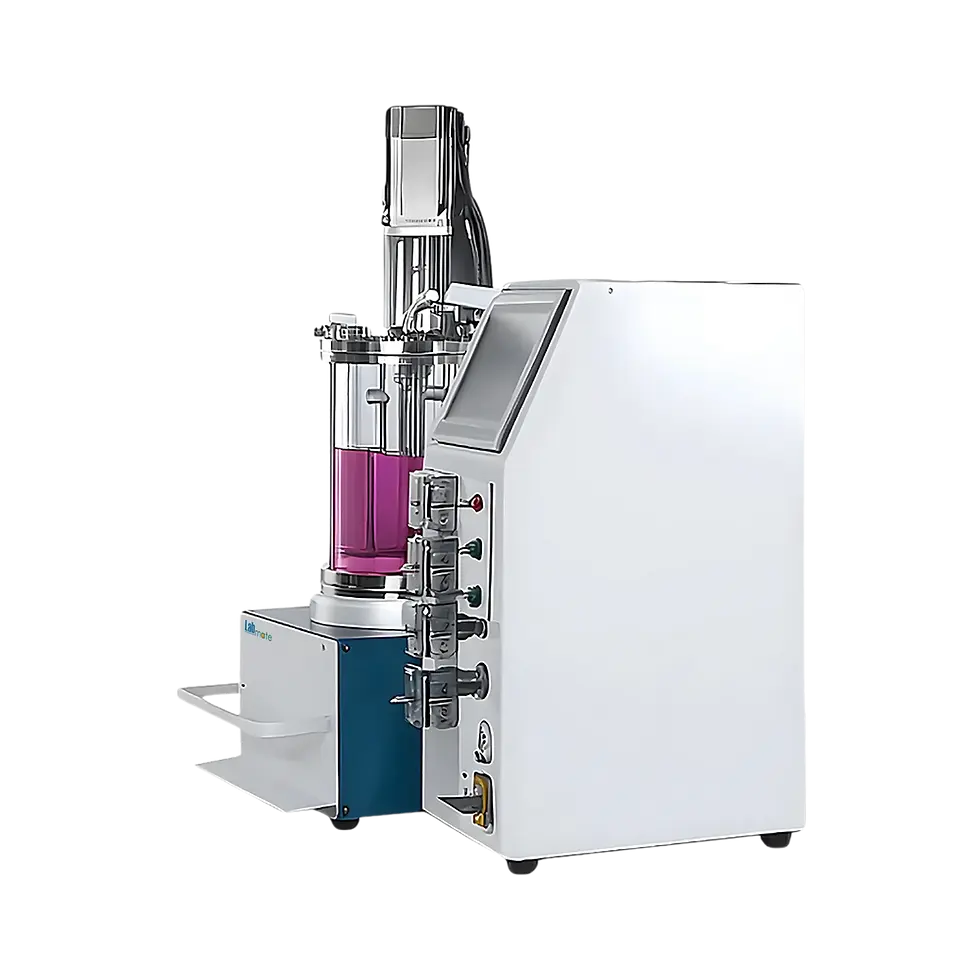

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A111

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A111 is a reliable and efficient sterilization solution for laboratory settings. This sterilizer is designed for use in medical, scientific, and pharmaceutical laboratories, offering a safe and effective method for sterilizing a wide range of equipment and materials. Equipped with a horizontal chamber and pulse vacuum technology, this sterilizer ensures thorough and uniform sterilization of items, reducing the risk of contamination and ensuring the safety of laboratory personnel. The LMPVS-A111 features a user-friendly interface and programmable controls, allowing for easy operation and customization of sterilization cycles. With its durable construction and advanced sterilization capabilities, the Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A111 is an essential addition to any laboratory looking for a reliable sterilization solution.

Product Info

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A111

Overview:

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A111 is a robust, mid-to-high capacity sterilization system designed for reliable steam-vacuum sterilization in laboratories, hospitals, pharmaceutical facilities, and industrial hygiene settings. With a 0.6 m³ stainless-steel chamber and advanced vacuum-pulse steam sterilization technology, this unit ensures deep, uniform steam penetration — even for bulky, porous, or wrapped items — while delivering consistent, safe sterilization cycles for instruments, media, glassware, and more.Key Features:

-

Vacuum-pulse steam sterilization — combines multiple vacuum and steam cycles to remove trapped air and achieve thorough penetration into dense or wrapped loads.

-

Automatic, microcomputer-controlled operation — enables programmable sterilization cycles, repeatable protocols, and minimal manual intervention.

-

Integrated steam generation with multi-channel steam intake & multi-stage heating — provides uniform steam and temperature distribution throughout the chamber.

-

Horizontal chamber design with V-shaped cavity base — facilitates efficient drainage, easy loading/unloading, and hygienic cleaning.

-

Durable stainless-steel construction — corrosion-resistant and built for long-term heavy use in demanding sterilization workflows.

-

Safety-oriented design — includes vacuum detection and leak monitoring to ensure process integrity and protect sterilization results.

Applications:

-

Sterilization of surgical and medical instruments, metal tools, and dental devices.

-

Sterilization of laboratory glassware, pipettes, culture vessels, containers, and general labware.

-

Sterilization of porous or wrapped items (e.g., dressings, bandages, sterilization packs, textiles).

-

Sterilization of liquids, culture media, reagents, and lab solutions in microbiology, biotech, pharmaceutical, or research labs.

-

High-throughput sterilization for hospital central sterilization units, environmental testing labs, veterinary clinics, food-processing labs, and other hygiene-sensitive facilities.

Specifications

Volume 0.6 m³ Design Temperature 144°C Sterilization Temperature Range 105°C to 139°C Inner Cavity Design Pressure -0.1 to 0.3 MPa Inner Cavity Working Pressure -0.1 / 0.25 MPa Jacket Design Pressure 0.3 MPa Jacket Working Pressure 0.25 MPa Inner Cavity Water Pressure Test 0.39 MPa Jacket Water Pressure Test 0.52 MPa Temperature Uniformity ±1°C Limiting Vacuum -94.3 kPa Leakage Rate Less than or equal to 1.3 kPa / 10 min Temperature Difference 15°C Power Consumption 2.4 kW Power Supply 380V, 50Hz Chamber Dimension 1180×610×910 mm Housing Dimensions 1440×1280×1940 mm Weight 1200 kg -