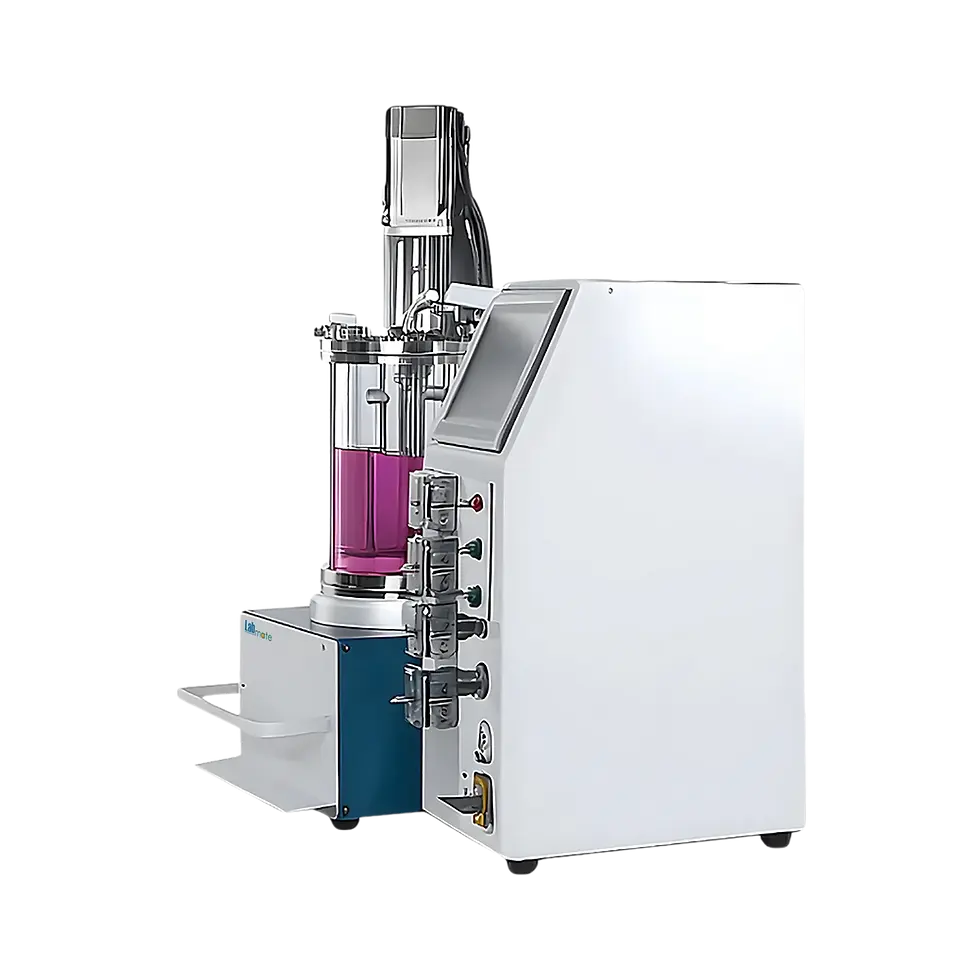

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A110

Introducing the Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A110, meticulously designed for superior sterilization performance. As an authorized distributor, winselluma presents this state-of-the-art device, ensuring optimal decontamination through its advanced pulse vacuum technology. Ideal for healthcare and laboratory environments, the sterilizer guarantees reliability, efficiency, and user-friendly operation. Trust winselluma for premium products and unparalleled customer service.

Product Info

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A110

Overview:

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A110 is a high-capacity, heavy-duty sterilization solution designed for large-scale, high-throughput sterilization tasks. Featuring a spacious 0.6 m³ stainless-steel chamber and advanced vacuum-pulse steam sterilization technology, this unit is engineered to deliver thorough steam penetration and consistent sterilization — even for bulky, porous, or wrapped loads. Its durable construction, automated controls, and safety-oriented design make it a reliable choice for hospitals, research labs, pharmaceutical facilities, food-processing plants, and industrial hygiene environments.Key Features:

-

Vacuum-pulse steam sterilization — alternating vacuum and steam cycles remove trapped air and ensure deep steam penetration, even in dense or wrapped loads.

-

Single-door horizontal chamber design with V-shaped base — optimizes drainage, simplifies loading/unloading, and ensures ease of cleaning.

-

Automatic microcomputer control with colour touchscreen interface — provides user-friendly, programmable sterilization cycles and customizable settings.

-

Multi-channel steam intake and multi-stage heating — ensures uniform steam and temperature distribution across the chamber for consistent sterilization performance.

-

Robust stainless-steel construction with advanced welding and electrolytic polishing — corrosion-resistant and built for long-term industrial use.

-

Built-in safety systems including vacuum detection, pressure and leak-rate monitoring — ensures airtight integrity and safe operation throughout sterilization cycles.

Applications:

-

Sterilization of surgical instruments, medical and dental tools, and stainless-steel implements.

-

Sterilization of laboratory glassware, pipettes, large lab vessels, containers, and bulk labware.

-

Sterilization of porous or wrapped items such as textiles, dressings, bandages, sterilization packs, and surgical kits.

-

Sterilization of culture media, reagents, liquids, and solutions in pharmaceutical, biotech, microbiology, and research labs.

-

High-throughput sterilization in hospital central sterilization departments, food-processing labs, veterinary clinics, environmental testing labs, and industrial hygiene facilities.

Technical Highlights:

Specification Value Chamber Volume 0.60 m³ Design Temperature 144 °C Sterilization Temperature Range 105 °C – 139 °C Inner Cavity Design Pressure –0.1 to 0.3 MPa Inner Cavity Working Pressure –0.1 / +0.25 MPa Jacket Design Pressure 0.3 MPa Jacket Working Pressure 0.25 MPa Inner-Cavity Water Pressure Test 0.39 MPa Jacket Water Pressure Test 0.52 MPa Temperature Uniformity ±1 °C Limiting Vacuum –94.3 kPa Maximum Leakage Rate ≤ 1.3 kPa per 10 min Chamber Dimensions 1180 × 610 × 910 mm Housing Dimensions 1440 × 1280 × 1940 mm Power Consumption 2.4 kW Power Supply 380 V, 50 Hz Unit Weight 1,200 kg -