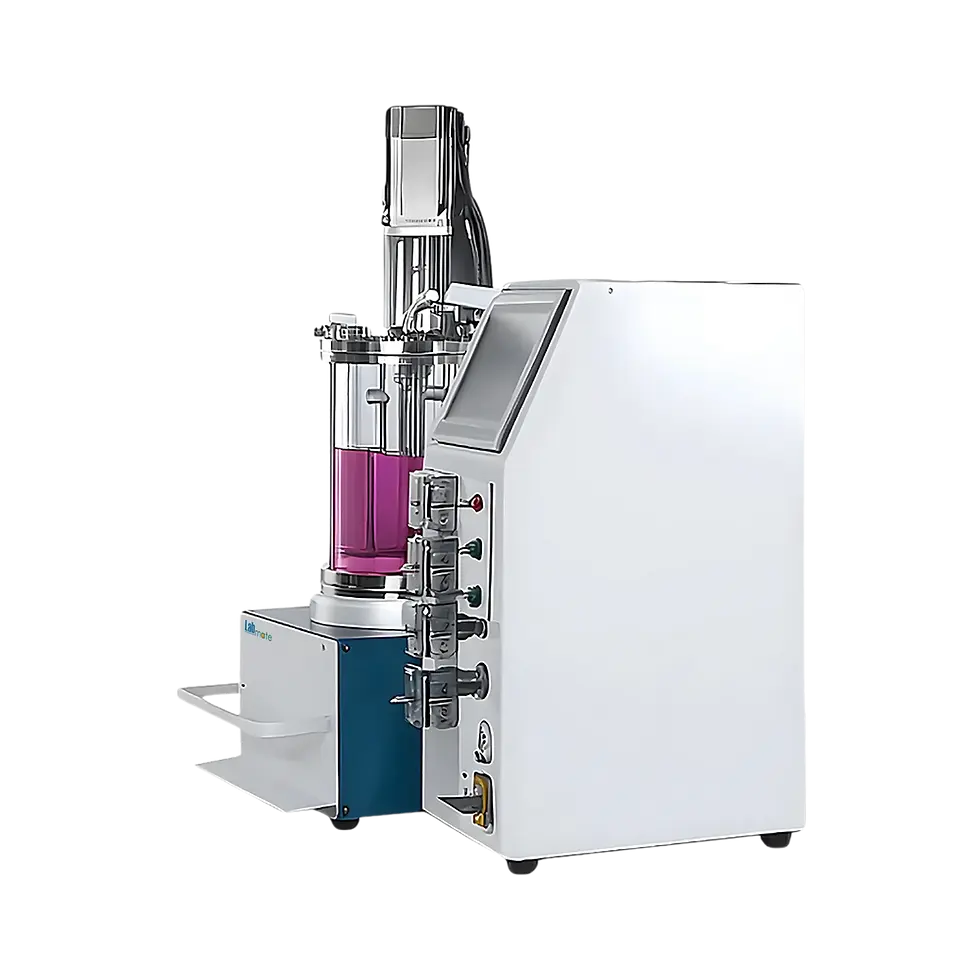

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A106

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A106 offers unmatched reliability and efficiency for all your sterilization needs. Designed for precision and ease of use, this advanced device ensures complete decontamination, suitable for various applications. winselluma is an authorized distributor, guaranteeing authentic products and exceptional customer support. Trust in our commitment to deliver high-quality, innovative solutions that meet your stringent standards. Enhance your operations with the Labmate LMPVS-A106 today.

Product Info

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A106

Overview:

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A106 is a high-performance sterilization system engineered for demanding sterilization requirements in medical, laboratory, pharmaceutical, food-processing, and industrial hygiene environments. Utilizing pulse-vacuum steam sterilization, this unit ensures deep steam penetration and uniform sterilization — even for solid instruments, glassware, fabrics, liquids, or wrapped materials. Built with a generous 0.36 m³ chamber, robust stainless-steel construction, and advanced control capabilities, it offers a reliable solution for high-throughput sterilization workflows while ensuring safety and durability.Key Features:

-

Vacuum-pulse steam sterilization — alternating vacuum and steam cycles eliminate trapped air and allow steam to penetrate deeply into porous or wrapped loads.

-

Automatic microcomputer control with colour touchscreen — enabling programmable sterilization cycles, easy operation, and reproducible results.

-

Multi-channel steam intake and multi-stage heating — providing uniform steam distribution and consistent sterilization throughout the chamber.

-

Single-door horizontal chamber design with four-sided V-shaped base — optimized for efficient drainage, easy loading/unloading, and simplified cleaning.

-

Safety-oriented design — includes vacuum detection, leak-rate monitoring, and built-in safety mechanisms for secure operation.

-

Durable stainless-steel construction with advanced welding and finishing — corrosion-resistant and built for long-term heavy use, suitable even for food-processing equipment sterilization.

Applications:

-

Sterilization of surgical instruments, medical and dental tools, laboratory metal implements.

-

Sterilization of glassware, pipettes, lab vessels, containers, and other labware.

-

Sterilization of fabrics, dressings or wrapped items requiring deep steam penetration.

-

Sterilization of culture media, reagents, liquids or other materials in biotech, pharmaceutical, food-processing, or clinical laboratories.

-

Sterilization in hospital sterilization units, veterinary clinics, environmental testing labs, and other high-hygiene industrial settings.

Technical Highlights:

Specification Value Chamber Volume 0.36 m³ Design Temperature 144 °C Sterilization Temperature Range 105 °C – 139 °C Inner-Cavity Design Pressure –0.1 to 0.3 MPa Inner-Cavity Working Pressure –0.1 / +0.25 MPa Jacket Design Pressure 0.3 MPa Jacket Working Pressure 0.25 MPa Inner Cavity Water Pressure Test 0.39 MPa Jacket Water Pressure Test 0.52 MPa Limiting Vacuum –94.3 kPa Leakage Rate ≤ 1.3 kPa per 10 min Temperature Uniformity ±1 °C Chamber Dimensions 1000 × 600 × 600 mm Housing Dimensions 1260 × 1270 × 1740 mm Power Consumption 1.2 kW Power Supply 380 V, 50 Hz Unit Weight 800 kg -