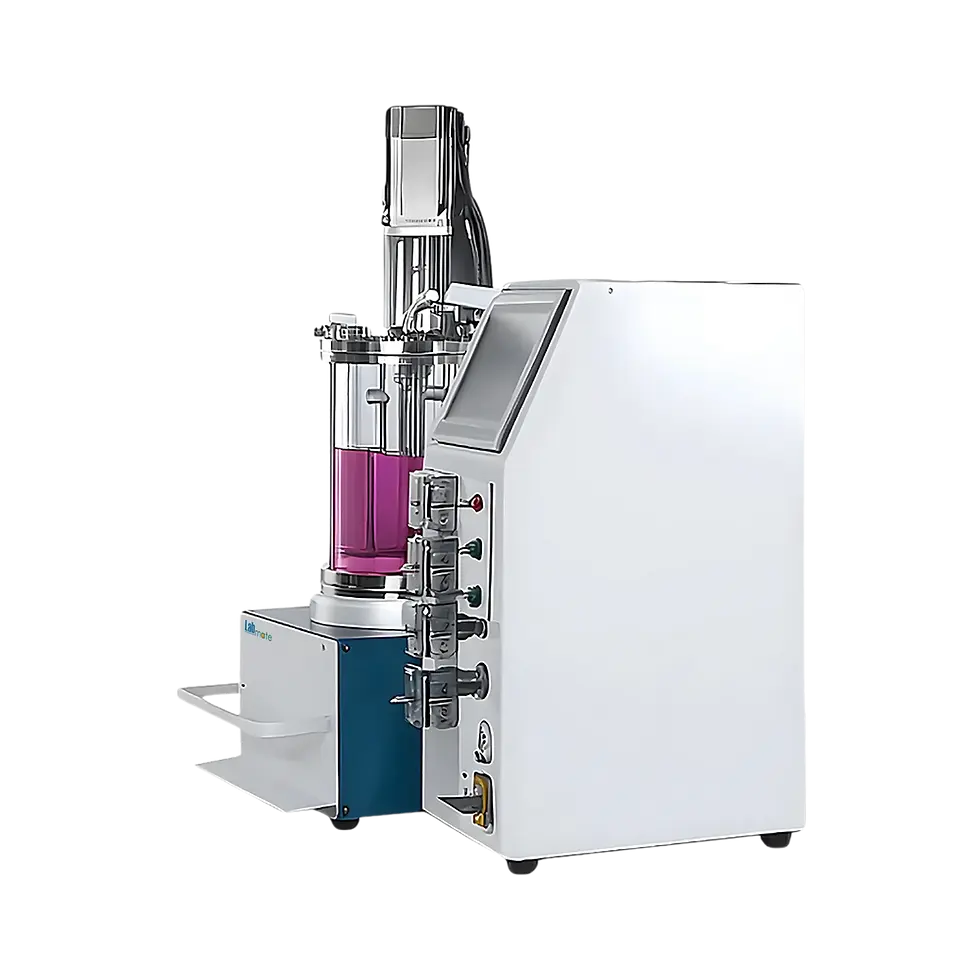

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A105

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A105 offers unparalleled efficiency and reliability for all your sterilization needs. Designed with advanced technology, it ensures precise temperature control and uniform heat distribution, catering to the demands of modern laboratories. Proudly available through winselluma, an authorized distributor, this high-performance sterilizer guarantees optimal results and user safety. Trust winselluma's commitment to quality and service excellence for all your laboratory equipment requirements.

Product Info

Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A105

Overview:

The Labmate Horizontal Pulse Vacuum Sterilizer LMPVS-A105 is a mid-to-large capacity sterilization system built for demanding sterilization needs in medical, laboratory, pharmaceutical, and industrial settings. With a 0.36 m³ chamber and advanced vacuum-pulse steam sterilization technology, this unit delivers deep, uniform steam penetration — ideal for instruments, glassware, fabrics, liquids, and wrapped or porous loads. Designed with durability, safety, and automation in mind, it is well suited for hospitals, biotech labs, food-processing facilities, and other high-hygiene environments.Key Features:

-

Vacuum-pulse steam sterilization — ensures thorough sterilization even for porous, wrapped, or irregular loads.

-

Integrated steam generator with multi-channel steam intake and multi-stage heating — self-contained steam source and uniform heat distribution.

-

Automatic microcomputer control with colour touch-screen — programmable sterilization cycles, easy operation, and repeatable workflows.

-

Double-door horizontal chamber with V-shaped cavity base — facilitates efficient loading/unloading, drainage, and internal cleaning.

-

Safety features including pressure controller, safety valve and vacuum leak detection — ensures safe, reliable operation cycle after cycle.

-

Robust stainless-steel construction — corrosion-resistant, durable, and built for long-term heavy use.

-

Auto water-management system — simplifies maintenance and ensures consistent performance.

Applications:

-

Sterilization of surgical instruments, medical and dental tools, metal implements.

-

Sterilization of laboratory glassware, pipettes, containers, and lab vessels.

-

Sterilization of porous/wrapped items such as fabrics, dressings, bandages, and sterilization packs.

-

Sterilization of liquids, media, reagents, culture fluids, and containers in pharmaceutical, biotech, microbiology, or food-processing labs.

-

Decontamination of equipment and materials in hospital sterilization departments, veterinary clinics, environmental testing labs, and industrial hygiene contexts.

Technical Highlights:

Specification Value Chamber Volume 0.36 m³ Design Temperature 144 °C Sterilization Temperature Range 105 °C – 139 °C Inner Cavity Design Pressure –0.1 to 0.3 MPa Inner Cavity Working Pressure –0.1 / +0.25 MPa Jacket Design Pressure 0.3 MPa Jacket Working Pressure 0.25 MPa Inner-cavity Water Pressure Test 0.39 MPa Jacket Water Pressure Test 0.52 MPa Temperature Uniformity ±1 °C Limiting Vacuum –94.3 kPa Leakage Rate ≤ 1.3 kPa per 10 min Chamber Dimensions 1000 × 600 × 600 mm Overall Housing Dimensions 1260 × 1270 × 1740 mm Power Consumption 1.2 kW Power Supply 380 V, 50 Hz Unit Weight 800 kg -