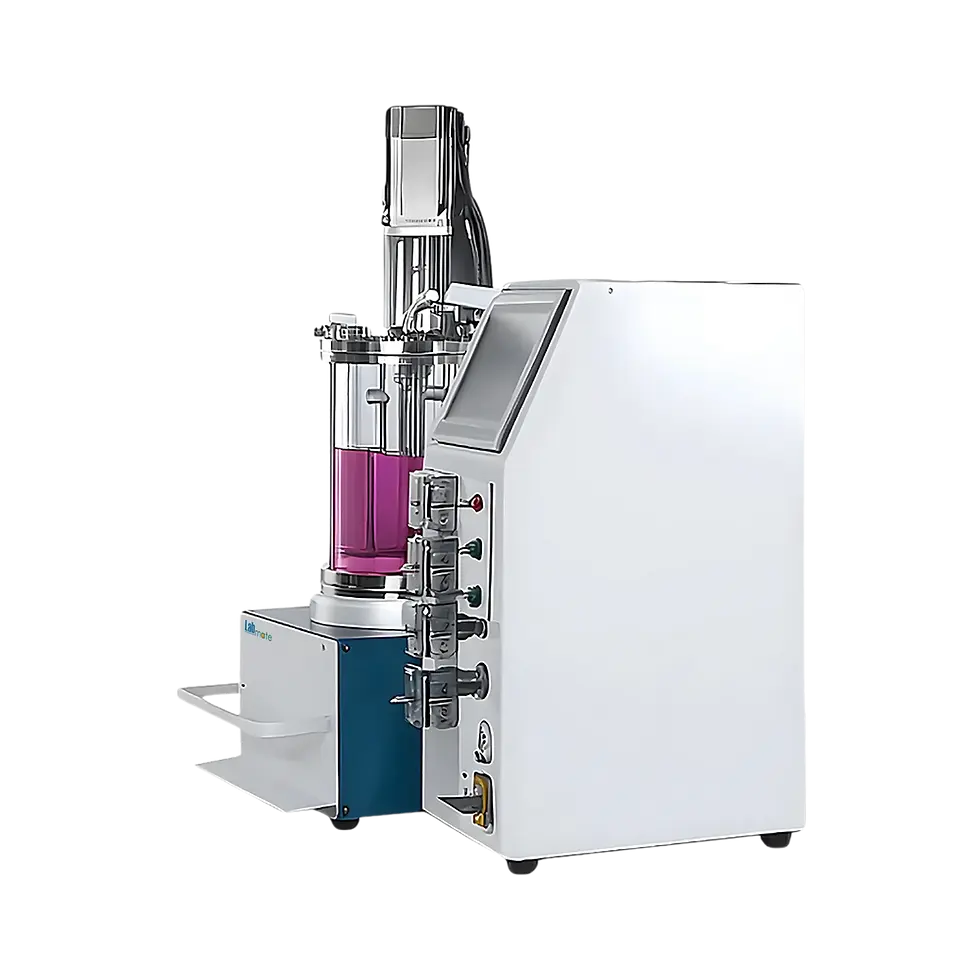

Infitek Fully Automatic Graphite Digestion Platform, GRD-60A

- Experience precision and efficiency with the Infitek Fully Automatic Graphite Digestion Platform, GRD-60A.

- Temperature control range of RT+5℃ to 300℃

- Accuracy of ±1℃

- Ensures consistent and reliable results

- Features two independent temperature control zones

- Capacity to handle up to 60 samples

- Designed to meet the rigorous demands of modern laboratories

- Enhance your sample digestion process with:

- Advanced technology

- Seamless operation tailored for high-throughput applications

PRODUCT INFO

“Fully automatic graphite digestion platform” is a pre-treatment equipment designed and produced according to the principle of wet digestion, and it is an ideal matching product for AES, AAS, AFS, ICP-MS and other analytical instruments.

It is an ” automatic sample processing platform” with the following process:

(1)Sample soaking process → (2) reagent automatic addition → (3) curve heating digestion → (4) automatic acid driving → (5) automat- ic constant volume → (8) automatic mixing. And Its advantage is the large sample processing capacity (60 samples/batch) with one-click completion, and there is no personnel needed to guard the process, therefore saying goodbye to monotonous, repetitive, cumbersome, dangerous sample processing work.

Features

1. Rotary oscillating and mixing technology – rotary oscillating and mixing has large amplitude and good mixing effect, and the swing amplitude is 5-10 times that of reciprocating technology.

Sample non-contact mixing – avoid cross contamination and loss of samples. The instrument can be used for oscillation, mixing, and setting of speed and time during process of adding liquid, cooling, constant volume, etc.2. Positive pressure with intelligent ventilation, anti-corrosion and anti-condensation water design: adopt the integral anti-corrosion material design, to ensure the long-term operation of equipment reliable.

3. Digestion equipment is completely enclosed: the powerful fan inhales fresh air and injects it into the control and implementation system of digestion equipment, where a positive pressure state is formed to prevent acidic gas from entering the fume hood. Acid mist of samples is wrapped by the positive pressure before going to the ventilation system.

4. Solve the problem of water vapor formation in the inside wall of fume hood:the reason for the formation of water vapor is the condensation phenomenon formed by the high temperature environment encountering low temperature conditions, and the key to solve this problem is to eliminate the internal and external temperature difference and remove the gas with a large water content, so that it cannot form condensation.

Intelligent internal and external environmental temperature determination, independent power supply system: solve the problem of time limit for stopping positive pressure and negative pressure ventilation.

5. The digestion equipment has a set of independent environmental temperature determination system and ventilation control system.

6. Even if the operator turns off its power switch, the system will maintain the ventilation state if there is large temperature difference between the inside and outside.7. Digestion and heating system adopts partition design:

The two digestion units can be controlled and operated independently or simultaneously, and the digestion module adopts graphite heater with good temperature uniformity and high temperature resistance.

Two independent temperature zones can be controlled and operated independently or simultaneously- Liquid supply system

Sample head-space system: the instrument is equipped with one air channel, which can be used for all the head-space

of the pre-reagent or the head-space at any position to prevent the reaction of different reagents.

The instrument is equipped with 8 reagent channels, with multiple reagent automatic switching functions, and each

reagent channel is independently controlled so that they will not affect each other.

The distilled water is supplied by independent pipeline (single module and double channel liquid adding pipeline) to

prevent reagent adding error caused by the same reagent pipeline.

Adding reagent adopts peristaltic pump with high precision and corrosion resistant, which can be calibrated at any time with high accuracy. - Instrument constant volume system

Use “high-precision ultrasonic liquid level sensor” to implement constant volume for any size digestion tube.

The finishing digestion tube cooperates with the above sensor to make the volumetric accuracy of 10ml-50ml ≤±1%. - Instrument temperature control system

Temperature control range: RT~300℃

Temperature control accuracy: ≤1℃

Adopt PID intelligent control

- Liquid supply system

Product Specification

Model name GRD-60A Temperature control range /temperature control accuracy RT+5℃-300℃ / 士 1℃ Temperature control zone/digestion unit 2 zones / 2 units Sample handling quantity/heating material 60 holes / graphite temperature control system PID intelligent control, 60 sections of program heating and single point heating mode. Constant volume mode/ Ultrasonic wave sensor Constant volume range/constant volume accuracy 1-50ml / ≤ 1%/5-50ml hour/ per time Reagent adding accuracy ≤0.5% Mixing mode/amplitude Rotation/vibration amplitude 20mm Mixing time About 0-99min Reagent channel 8 channels Anti-corrosion and anti-condensation design Positive pressure ventilation, with anti – corrosion,anti – condensation water system, and independent power supply Internal and external environment temperature determination system Equipped Working voltage AC220V/50Hz ±10% Heating power 4KW Fume hoods Equipped Net size (L*W*H) 650*1020*1400mm